Battery Management System

LEM works with all the major car manufacturers and Tier-1 suppliers in the world, and supplies galvanically-isolated electronic transducers that measure electrical parameters in battery-management and motor-control applications.

SMART AUTOMOTIVE BATTERY MANAGEMENT TO REDUCE OVERALL ENERGY CONSUMPTION

LEM Automotive is specialized in developing and manufacturing current transducers for battery management and motor drive applications in cars, buses and trucks. By controlling the current in energy-intensive applications, LEM participates in the global effort to reduce overall energy consumption.

Typical applications for automotive transducers include:

- Standard battery monitoring

- Hybrid and EV battery pack current sensing

- Fuel cell current control

- DC/DC converters and AC/DC inverters

- Hybrid and EV motor inverter drive

- EPS and X-by-wire applications

- Electric compressors for air conditioning

See also: Automotive Motor Control

APPLICATIONS FOR AUTOMOTIVE BATTERY MANAGEMENT

Conventional battery management

Car makers have been focusing their attention on reducing fuel consumption for several years. Currently, the main focus is to reduce fuel usage by managing the charging of the main battery. Early progress in energy management has now shifted focus and is heavily concerned with power management. This includes managing the battery, the combination of additional functions of the battery’s state of health and safety features, such as auto-disconnect. Secondary functions have been reduced and the size of the alternator has been optimized thus instantly reducing global electrical consumption.

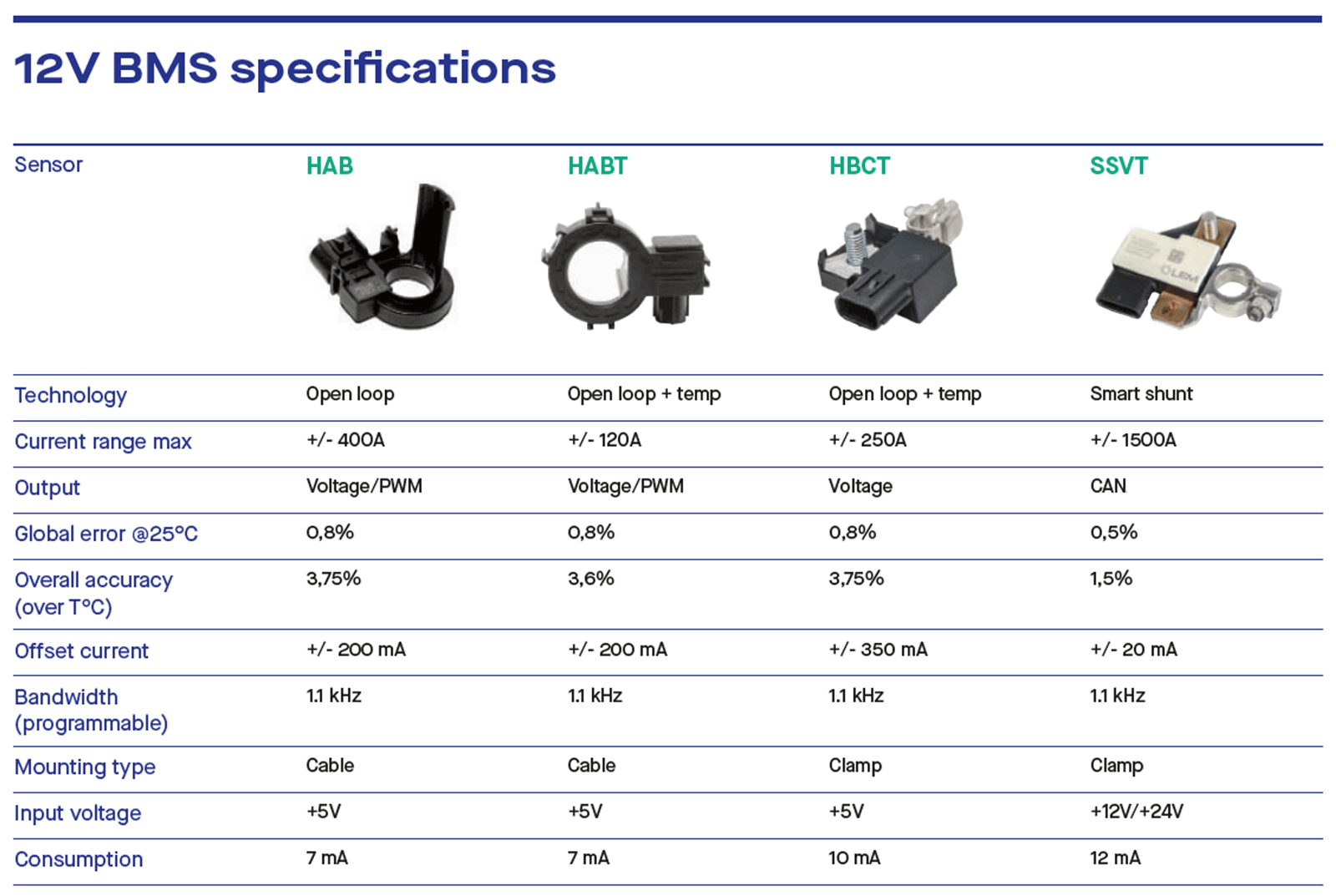

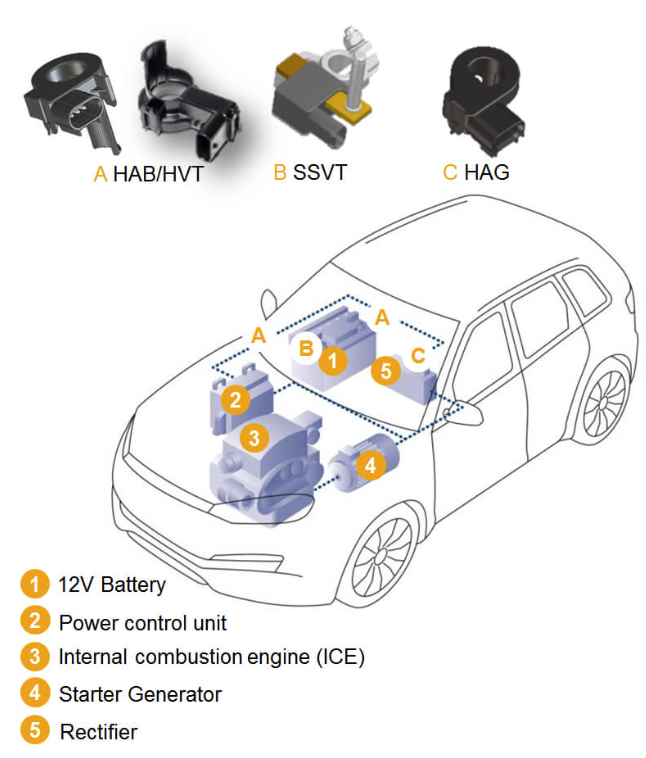

Hall-effect sensors (HAB, HABT, HAG, HAH1) and Smart Shunt (SSVT) are the product of choice for this application.

In our example above, the current sensors (HAB/HVT and SSVT) allow the battery management system (BMS) to decide if enough energy is available in the battery to operate the accessories (such as aid-conditioning, headlights, and radio) while the engine is off, and still have ample charge left to restart the engine.

The "engine control unit" will instruct the "starter generator" to restart the engine or recharge the battery, as needed, and current sensors (HAG) used at the output of the rectifier modules allow it to operate smoothly, improving the driver experience while helping the environment.

Generator current monitoring

The need for higher energy in cars is increasing. Generators are required to provide more current to the vehicle loads and batteries, yet to be more efficient, the current needs to be controlled. The HAB and HAG current sensor families are best suited to provide the BMS (Battery Management System) with the proper current information. Depending on the size of the car, this current can flow from 60A (conventional car) up to 240A (service cars and trucks).

Battery management for hybrid and EV markets

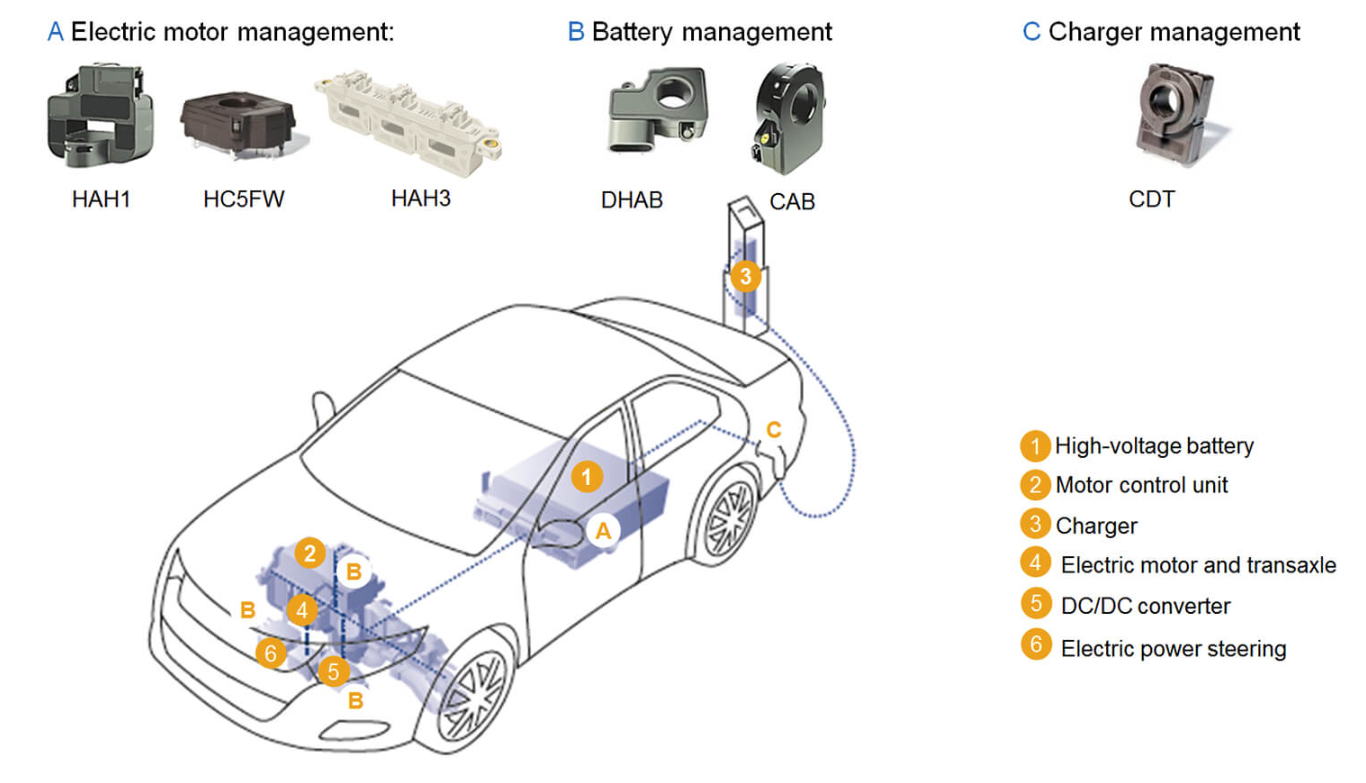

The production of electric car and hybrid vehicles is increasing.

Both types of vehicle need high current capability batteries to run the 50kW or more motors and these use high voltage systems. The current sensors for these batteries need to be isolated.

Flux Gate Sensors (CAB) and Hall-effect sensors (HAH1, HSN, DHAB) are the product of choice for this application.

Car Application (PHEV) : Electric Plug-In Car

High Voltage Battery Management System Products (HV BMS)

Application example

Quality

LEM products meet all quality requirements for the automotive industry and comply with RoHS specifications. All our production and development centers are certified with ISO TS 16949 (in Switzerland and in China). Based on our deep knowledge of applications and current measurement technologies, LEM develops both catalog and customized products which can be perfectly tailored to meet your needs in terms of performance, space requirement and cost.

For more information, please feel free to contact us using the following email address: web_automotive_sales@lem.com

PRODUCT DOCUMENTATION

Need help with a project?

You have a project in line with that application and want to discuss it with LEM?

Click on the contact button below and our experts will help you find the best solutions for your needs.